So…we’re getting down (mostly) to the small stuff. At least for me. Ann still has a couple of big sewing projects. More on that below.

We think Charisma is getting excited about heading out again. She's sure looking good.

Yesterday, Ann put wood oil on the cockpit teak (protects the wood, but not slippery). We had cleaned and bleached the grey wood a couple days ago and were waiting for it to dry before oiling.

Always nice to see the teak with that new "honey" color that you get after bleaching.

Once it's dry, we add teak oil to protect the wood and keep it from turning the ash grey color that some people like, but it's not Ann's favorite. This better matches the new varnish work.

Ann’s also been sewing up a storm. She warmed up with a couple of canvas covers. One for the hydro-generator in the cockpit to (hopefully) keep it from rusting again and the other, a cover for the watermaker high pressure pump (pictured below). It’s in a vulnerable spot right under the head porthole where it’s easy for a wave or rain to splash it. I’ve been just throwing a rag over the top of it, but this is a bit more elegant looking.

This covers the exposed electric pump that provides the first stage pressure to the watermaker.

Warmed up now, she’s tackled the “big one”. Ann’s making a rain cover for the cockpit for those rainy days sitting at anchor. With a cover we can still sit in the cockpit instead of having to retreat to the hot and humid cabin.

We moved the big blue monster (the Sailrite sewing machine) up to the BBQ gazebo where it's easier to spread out.

I’ve been picking off lots of small stuff that I never get around to because it’s never quite important enough…One such project that I got an inspiration for how to attack was the cockpit light. We bought a nice LED last year in Fiji that hangs just inside the dodger and the cable snakes inside the fabric that covers the structure down to the cabin top. From there I’ve just been pulling it through the quarter berth porthole and connecting it inside the electronics cabinet circuit breakers whenever we anchor. The problem with this (beside an errant cable snaking across the cabin and having to screw it onto a circuit breaker when we want to use it, is that when it rains the porthole can’t be closed. When it rains really hard – usually in the middle of the night – rain starts to pour in and we have to jump up and unscrew the wires, throw the cable out the porthole and then close it. It’s a bit of a “kludge” but it worked. Sort of. And it solved the problem of how to connect the darn thing. The light is physically located a long way from any regular circuit that is easily accessible for a permanent connection. I thought.

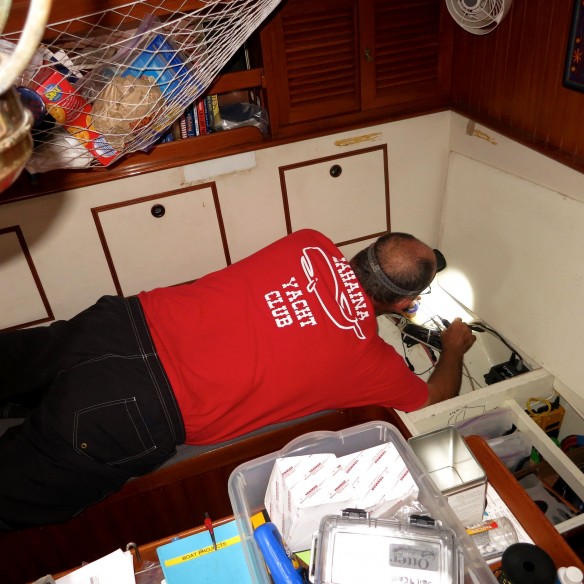

Well, yesterday I had an inspiration. I realized I could drill a little hole through the cabin top right where the wire came down the dodger structure – virtually unseen – and into the cabin inside the overhead covering it would be right next to a cabin light and the wires would be invisible, tucked away above the ceiling. The cabin light has a switch, but upstream of the switch is 12 volts so we wouldn’t be dependent on the cabin light switch. OK, but what kind of switch could I use and where would I put it? This is one of the things that’s kept me from even thinking about this. I thought there was no where I could elegantly put a switch that wouldn’t look completely out of place, hacked into a wall or ceiling somewhere. Then I realized I could simply drill a hole in the side of the existing light fixture and add a second toggle switch (pictured). Yay! It looks like it was done at the factory. No more midnight porthole races. We can toggle the cockpit light on and off to our heart’s content.

Light in the cockpit. A great thing. No more dinner by headlamp. The new switch is the one on the right.

Silly how I can be so excited about these little projects, but each one makes life on the boat just a little easier. It adds up. Who knows, maybe someday we’ll put in a shower so we don’t have to take our baths naked in the cockpit, with warm water out of a teapot.

Nah.