Fulunga. SW Lau Group, Fiji

We made it to Fulunga! This certainly has to be the most beautiful place in the world. Words cannot really do justice to just how beautiful and idyllic this place is. I also can’t quite find the words to describe how happy both of us are to be here. We have already seen several of the locals we met last year and one (Alfredi) already came past Charisma on his canoe and gave us some oranges he has been cultivating. ( I think his stash is a secret, as he paddles out to go fishing in the lagoon and comes back with the oranges). Anyway, we’ll have much more to say about Fulunga as we plan to do our Sevusevu tomorrow and go to church on Sunday (it’s Friday night here in Fiji right now). So…why did we not do sevusevu today? After all we got in early and had dropped anchor by 1000. Weelllllll….our Monitor Wind Vane broke yesterday and we spent yesterday afternoon and all last night hand steering (oh, the horror!). We have no autopilot and rely on “Wilson” to get us from place to place. In fact we sometimes secretly snicker at people whose complex electro-hydraulic autopilots conk out. You know the saying; “It’s not IF your autopilot breaks, it’s WHEN”. Well, karma smacked us on the butt yesterday. I was sleeping, or at least trying to, when Ann came down and said; “there’s something wrong with the wind vane. Dragging myself out of bed and into the cockpit it took about three seconds to see that the entire water vane (the part that steers in the water) had broken off and was floating behind us, hanging on its emergency cord that keeps us from losing it. That was the good news. The bad news was it was unfixable while underway. There was no doubt we were going to have to hand steer the whole second half of the trip. No reading, no games on the iPad, no napping under the dodger. Just hands on the wheel. Turns out what they call the “Watervane Pivot Shaft” broke. This is the main shaft that holds the rudder part of the vane. The weld that holds the shaft to the big stainless steel plate that attaches to the hinge parted. I was bummed.

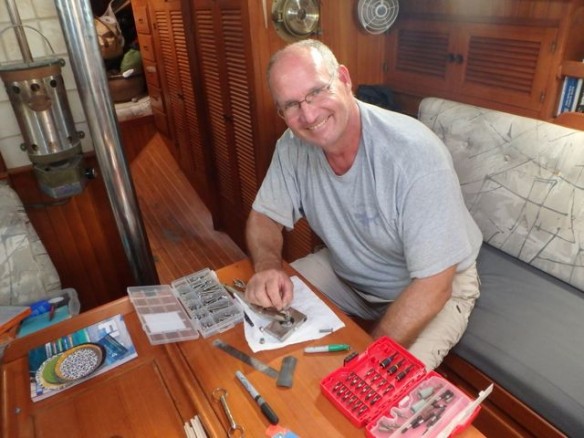

Only one thing to do. Pull the thing out of the water (thank goodness for the tether), tie it to the stern pushpit and set up a new watch schedule. No more five hour watches. When you have to hand steer at night, three hours is about the most you can do before your eyes start bouncing up and down in their sockets and you go into periods of “micro-sleep” where you think you are steering 130 degrees, but the compass really says “150 degrees”. So we got here, a little broken, but intact. I was mentally counting all the hours we would have to hand steer over the next 4 to 5 weeks as we cruise the Lau Group of islands here in the eastern Fiji, but as luck would have it our Canadian friends on Katie M II were here in Fulunga. Martin built his boat and is a good hand with tools (to say the least). He took one look at the Monitor and said; “I think you can fix this by drilling a couple holes in the stainless steel plate and then bolting it back onto the shaft”. Yeah, right, Martin. In your dreams. I don’t have the kind of “firepower” in tools to drill through inch and a half stainless. But since he volunteered to help, I saw a chance to actually jury rig the darn thing until we can get a new part from Monitor. “Go for it!” says I. He did and we then took the broken part and with some more brutal drilling from the dinghy, Ann and I matched the holes and drilled through the broken ¼ inch shaft.

Now we could bolt it back together where the weld had once held the part. Oh and one other thing. There was a roller bearing that fell out when the thing broke. The good news is I had parts. The bad news is the roller bearing actually just consists of 31 plastic rolling pins about 1/16 inch wide by 3/8 tall. You have to somehow stick them UP into the shaft before putting the base back on. Oh, and did I mention this is over the water on the back of the boat? We were working on this from the dinghy. We had a big bucket under the thing so any parts that dropped could be retrieved instead of dropping into 25 feet of water. The most interesting part was the use of shaving cream. “HUH?” you ask?? Yep, the only way to get all 31 of the darn little plastic roller bearings UP into the shaft was to put shaving cream on a washer and then “stick” the bearings on it before lifting (very carefully) the whole thing up onto the shaft. This was Ann’s idea and it was a winner. It worked!! The whole assembly looked something like a birthday cake with the white shaving cream with all the plastic bearings sticking up through it.

OK, I’m rambling now because I/we are thrilled that a potential BIG problem has been solved through the help of our friend Martin and four hours work and I have only had a few hours sleep in the last 36 hourss. Now we can get on with our adventure in paradise. And, both Ann and I can notch another unusual and unexpected boat repair in our resume.

Have fun!

Wow! Good job fixing the “vane”, good luck running into Martin, and good thing Ann is so creative!

You two are the most inventive, creative, ingenious, adaptive people I know. What a story. You have proven, once again, invention is the mother of necessity. Well done and what a relief. Now on to other, less stressful, adventures.